iron ore grinding crushing uzbekistan

IOM3 Uzbek mining complex on the horizon

2021年9月27日The established energy efficient High Pressure Grinding Roll (HPGR) technology, will be used to help process up to 60 million tons of iron ore per year. The

进一步探索Uzbekistan kicks off $4.9 billion copper mining Uzbekistan to construct new mining and metallurgical

Dentons Dentons Global Mining Guide: Uzbekistan

2022年1月17日Uzbekistan is among the top 15 countries with the largest uranium and copper reserves. As reported by the State Geology Committee (GeoCom) in 2018, only

进一步探索Uzbekistan: Mining, Minerals and Fuel ResourcesMining Industry Of Uzbekistan Mining Uzbekistan

Research into the crushing and grinding processes of iron ore with

Testing of iron ore samples for uniaxial and bulk unequal component compression accompanied by UHF electric field has helped determine a tendency to obtain more

作者: Petro Shcherbakov, Svitlana Tymchenko, Olha Buhrym, Dina Klymenko

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A

(PDF) Research into the crushing and grinding

2019年1月1日Research into the crushing and grinding processes of iron ore with its simultaneous effect by mechanical load and electric field of ultra-high frequency.

Find Metal Ore Mining Companies in Uzbekistan DunBradstreet

Find detailed information on Metal Ore Mining companies in Uzbekistan, including financial statements, sales and marketing contacts, top competitors, and firmographic insights.

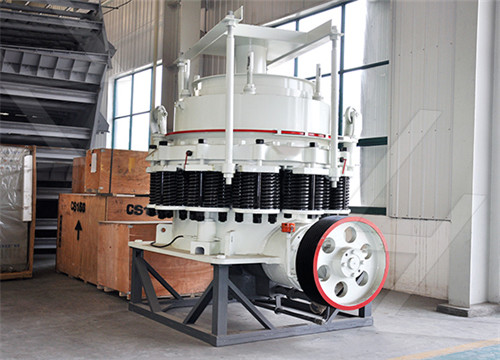

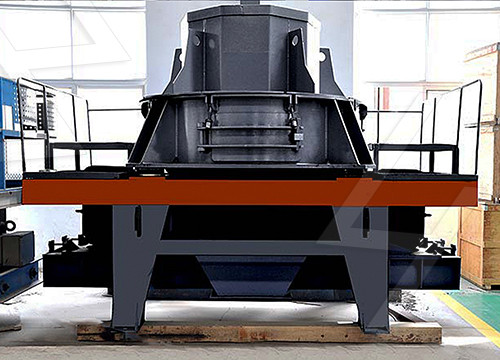

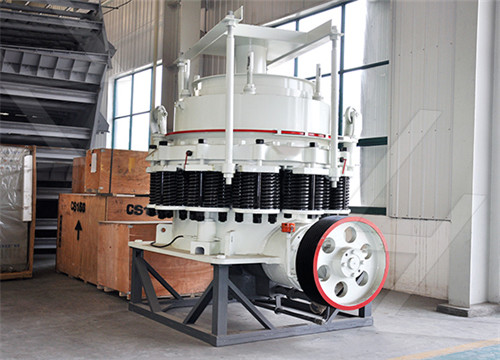

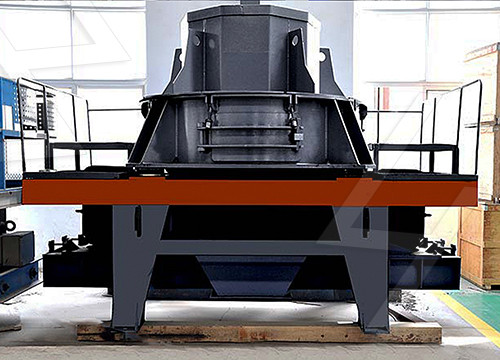

Uzbekistan Machines; for crushing or grinding earth, stone, ores or

Uzbekistan imported Machines; for crushing or grinding earth, stone, ores or other mineral substances from China ($74,346.36K,5,022 Item), Lithuania ($60,229.21K,52

Uzbekistan Machines; for crushing or grinding earth, stone, ores or

Uzbekistan imported Machines; for crushing or grinding earth, stone, ores or other mineral substances from China ($141,701.67K,1,117 Item), Germany ($30,537.04K,41

Machines; for crushing or grinding earth, stone, ores or other

In 2019, Top exporters of Machines; for crushing or grinding earth, stone, ores or other mineral substances to Uzbekistan were China ($27,698.42K,576 Item), European

Enter Engineering, thyssenkrupp to tackle Tebinbulak

2021年9月27日HPGR has been used since 1985 in the cement industry, and since 1986 in the mining industry for use in the grinding process to ensure a high level of product fineness. Full integration of this technology

Research of iron ore grinding in a vertical-roller-mill

2015年3月15日Vertical-roller-mills (VRM) are an energy-efficient alternative to conventional grinding technology. One reason is the dry in-bed grinding principle. Results of extensive test works with two types of magnetite iron ores in a Loesche VRM are presented here. Within these test works, mill parameters like grinding pressure,

(PDF) Research into the crushing and grinding

2019年1月1日Research into the crushing and grinding processes of iron ore with its simultaneous effect by mechanical load and electric field of ultra-high frequency January 2019 E3S Web of Conferences 123(89

Research of iron ore grinding in a vertical-roller-mill

2015年3月15日Iron ores Comminution Grinding Shear forces Ore mineralogy Nomenclature Ao mass specific surface Blib ratio of liberation H dam ring height k regression coefficient mProd production rate nS separator speed P80 80% passing size pFl grinding pressure Q3 cumulative passing R2

Toward the influence of iron oxide morphology on the grinding

2018年8月17日The present study demonstrates the effect of the different morphological types on the cold crushing strength (CCS) of heat-treated iron ore pellets. Blends with different iron ore oxides morphologies were subjected to grinding, filtering and pot grate tests on industrial scale trials. Results of grinding tests showed the hematite-goethite

The six main steps of iron ore processing Multotec

The six main steps of iron ore processing When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage.

Iron Ore production in the Pilbara

locomotives, 230 ore cars and is over 2.4 kilometres long. A single driver, supported by centralised track control, operates the train. Ore car dumping Once the train arrives at the port the ore cars go through the car-dumper. The ore cars are rotated and the ore flows out into bins and then is discharged onto conveyors. Stockpile

Developments in iron ore comminution and classification

2015年1月1日Hematite and magnetite, the two predominant iron ores, require different processing routes. High-grade hematite direct shipping ores (DSOs) generally only require crushing and screening to meet the size requirements of lump (typically between 6 and 30 mm) and fines (typically less than 6 mm) products.Low-grade hematite ores require

Muruntau Gold Mine Mining Technology

2021年10月8日It is also the world’s fifth deepest open-pit mine. It produces 66t gold per annum. The state-owned company, Navoi MiningMetallurgical Combinat (NGMK) owns and operates the mine. The mine was discovered in 1958. It measures about 3.5km by 3km and has a current mining depth of 600m, which is planned to be extended beyond 1,000m.

Investigation on Iron Ore Grinding based on Particle Size Distribution

2020年5月28日The feed samples of X, Y, and Z iron ores were ground in the BBM (ball mill refers to a BBM of size 300 mm × 300 mm with smooth liners) to identify the PSD, BWI, and RT of each ore. Grinding experiments were conducted according to Bond’s standard test procedure [].For each iron ore sample, the RT taken to produce 250% circulating

Enter Engineering, thyssenkrupp to tackle Tebinbulak

2021年9月27日HPGR has been used since 1985 in the cement industry, and since 1986 in the mining industry for use in the grinding process to ensure a high level of product fineness. Full integration of this technology

(PDF) Research into the crushing and grinding

2019年1月1日Research into the crushing and grinding processes of iron ore with its simultaneous effect by mechanical load and electric field of ultra-high frequency Authors: Petro Shcherbakov Dnipro...

Toward the influence of iron oxide morphology on the grinding

2018年8月17日The present study demonstrates the effect of the different morphological types on the cold crushing strength (CCS) of heat-treated iron ore pellets. Blends with different iron ore oxides morphologies were subjected to grinding, filtering and pot grate tests on industrial scale trials. Results of grinding tests showed the hematite-goethite

Iron Ore production in the Pilbara

locomotives, 230 ore cars and is over 2.4 kilometres long. A single driver, supported by centralised track control, operates the train. Ore car dumping Once the train arrives at the port the ore cars go through the car-dumper. The ore cars are rotated and the ore flows out into bins and then is discharged onto conveyors. Stockpile

Research of iron ore grinding in a vertical-roller-mill

2015年3月15日Iron ores Comminution Grinding Shear forces Ore mineralogy Nomenclature Ao mass specific surface Blib ratio of liberation H dam ring height k regression coefficient mProd production rate nS separator speed P80 80% passing size pFl grinding pressure Q3 cumulative passing R2

Muruntau Gold Mine Mining Technology

2021年10月8日It is also the world’s fifth deepest open-pit mine. It produces 66t gold per annum. The state-owned company, Navoi MiningMetallurgical Combinat (NGMK) owns and operates the mine. The mine was discovered in 1958. It measures about 3.5km by 3km and has a current mining depth of 600m, which is planned to be extended beyond 1,000m.

Investigation on Iron Ore Grinding based on Particle Size Distribution

2020年5月28日The feed samples of X, Y, and Z iron ores were ground in the BBM (ball mill refers to a BBM of size 300 mm × 300 mm with smooth liners) to identify the PSD, BWI, and RT of each ore. Grinding experiments were conducted according to Bond’s standard test procedure [].For each iron ore sample, the RT taken to produce 250% circulating

Comparing strategies for grinding itabirite iron ores in

2021年3月15日Comminution circuits that have been frequently used in the Brazilian iron ore industry in preparation of high-grade iron ores consist of multiple crushing stages followed by ball milling and are known for being highly

Dentons Dentons Global Mining Guide: Uzbekistan

2022年1月17日Uzbekistan is among the top 15 countries with the largest uranium and copper reserves. As reported by the State Geology Committee (GeoCom) in 2018, only

Research into the crushing and grinding processes of iron ore with

Testing of iron ore samples for uniaxial and bulk unequal component compression accompanied by UHF electric field has helped determine a tendency to obtain more

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A

(PDF) Research into the crushing and grinding

2019年1月1日Research into the crushing and grinding processes of iron ore with its simultaneous effect by mechanical load and electric field of ultra-high frequency.

Find Metal Ore Mining Companies in Uzbekistan DunBradstreet

Find detailed information on Metal Ore Mining companies in Uzbekistan, including financial statements, sales and marketing contacts, top competitors, and firmographic insights.

Uzbekistan Machines; for crushing or grinding earth, stone, ores or

Uzbekistan imported Machines; for crushing or grinding earth, stone, ores or other mineral substances from China ($74,346.36K,5,022 Item), Lithuania ($60,229.21K,52

Uzbekistan Machines; for crushing or grinding earth, stone, ores or

Uzbekistan imported Machines; for crushing or grinding earth, stone, ores or other mineral substances from China ($141,701.67K,1,117 Item), Germany ($30,537.04K,41

Machines; for crushing or grinding earth, stone, ores or other

In 2019, Top exporters of Machines; for crushing or grinding earth, stone, ores or other mineral substances to Uzbekistan were China ($27,698.42K,576 Item), European

Enter Engineering, thyssenkrupp to tackle Tebinbulak

2021年9月27日HPGR has been used since 1985 in the cement industry, and since 1986 in the mining industry for use in the grinding process to ensure a high level of product fineness. Full integration of this technology

Research of iron ore grinding in a vertical-roller-mill

2015年3月15日Vertical-roller-mills (VRM) are an energy-efficient alternative to conventional grinding technology. One reason is the dry in-bed grinding principle. Results of extensive test works with two types of magnetite iron ores in a Loesche VRM are presented here. Within these test works, mill parameters like grinding pressure,

(PDF) Research into the crushing and grinding

2019年1月1日Research into the crushing and grinding processes of iron ore with its simultaneous effect by mechanical load and electric field of ultra-high frequency January 2019 E3S Web of Conferences 123(89

Research of iron ore grinding in a vertical-roller-mill

2015年3月15日Iron ores Comminution Grinding Shear forces Ore mineralogy Nomenclature Ao mass specific surface Blib ratio of liberation H dam ring height k regression coefficient mProd production rate nS separator speed P80 80% passing size pFl grinding pressure Q3 cumulative passing R2

Toward the influence of iron oxide morphology on the grinding

2018年8月17日The present study demonstrates the effect of the different morphological types on the cold crushing strength (CCS) of heat-treated iron ore pellets. Blends with different iron ore oxides morphologies were subjected to grinding, filtering and pot grate tests on industrial scale trials. Results of grinding tests showed the hematite-goethite

The six main steps of iron ore processing Multotec

The six main steps of iron ore processing When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage.

Iron Ore production in the Pilbara

locomotives, 230 ore cars and is over 2.4 kilometres long. A single driver, supported by centralised track control, operates the train. Ore car dumping Once the train arrives at the port the ore cars go through the car-dumper. The ore cars are rotated and the ore flows out into bins and then is discharged onto conveyors. Stockpile

Developments in iron ore comminution and classification

2015年1月1日Hematite and magnetite, the two predominant iron ores, require different processing routes. High-grade hematite direct shipping ores (DSOs) generally only require crushing and screening to meet the size requirements of lump (typically between 6 and 30 mm) and fines (typically less than 6 mm) products.Low-grade hematite ores require

Muruntau Gold Mine Mining Technology

2021年10月8日It is also the world’s fifth deepest open-pit mine. It produces 66t gold per annum. The state-owned company, Navoi MiningMetallurgical Combinat (NGMK) owns and operates the mine. The mine was discovered in 1958. It measures about 3.5km by 3km and has a current mining depth of 600m, which is planned to be extended beyond 1,000m.

Investigation on Iron Ore Grinding based on Particle Size Distribution

2020年5月28日The feed samples of X, Y, and Z iron ores were ground in the BBM (ball mill refers to a BBM of size 300 mm × 300 mm with smooth liners) to identify the PSD, BWI, and RT of each ore. Grinding experiments were conducted according to Bond’s standard test procedure [].For each iron ore sample, the RT taken to produce 250% circulating

Enter Engineering, thyssenkrupp to tackle Tebinbulak

2021年9月27日HPGR has been used since 1985 in the cement industry, and since 1986 in the mining industry for use in the grinding process to ensure a high level of product fineness. Full integration of this technology

(PDF) Research into the crushing and grinding

2019年1月1日Research into the crushing and grinding processes of iron ore with its simultaneous effect by mechanical load and electric field of ultra-high frequency Authors: Petro Shcherbakov Dnipro...

Toward the influence of iron oxide morphology on the grinding

2018年8月17日The present study demonstrates the effect of the different morphological types on the cold crushing strength (CCS) of heat-treated iron ore pellets. Blends with different iron ore oxides morphologies were subjected to grinding, filtering and pot grate tests on industrial scale trials. Results of grinding tests showed the hematite-goethite

Iron Ore production in the Pilbara

locomotives, 230 ore cars and is over 2.4 kilometres long. A single driver, supported by centralised track control, operates the train. Ore car dumping Once the train arrives at the port the ore cars go through the car-dumper. The ore cars are rotated and the ore flows out into bins and then is discharged onto conveyors. Stockpile

Research of iron ore grinding in a vertical-roller-mill

2015年3月15日Iron ores Comminution Grinding Shear forces Ore mineralogy Nomenclature Ao mass specific surface Blib ratio of liberation H dam ring height k regression coefficient mProd production rate nS separator speed P80 80% passing size pFl grinding pressure Q3 cumulative passing R2

Muruntau Gold Mine Mining Technology

2021年10月8日It is also the world’s fifth deepest open-pit mine. It produces 66t gold per annum. The state-owned company, Navoi MiningMetallurgical Combinat (NGMK) owns and operates the mine. The mine was discovered in 1958. It measures about 3.5km by 3km and has a current mining depth of 600m, which is planned to be extended beyond 1,000m.

Investigation on Iron Ore Grinding based on Particle Size Distribution

2020年5月28日The feed samples of X, Y, and Z iron ores were ground in the BBM (ball mill refers to a BBM of size 300 mm × 300 mm with smooth liners) to identify the PSD, BWI, and RT of each ore. Grinding experiments were conducted according to Bond’s standard test procedure [].For each iron ore sample, the RT taken to produce 250% circulating

Comparing strategies for grinding itabirite iron ores in

2021年3月15日Comminution circuits that have been frequently used in the Brazilian iron ore industry in preparation of high-grade iron ores consist of multiple crushing stages followed by ball milling and are known for being highly