impact stone crusher installation plant design

(PDF) Design of Impact stone crusher machine

2019年5月31日The main objective is to design impact stone crusher. Impact stone crusher involves the use of impact rather than pressure

Industrial Solutions Impact crushers ThyssenKrupp

burden and stone; for the selective crushing of ore-bearing material; in the chemical industry for pyrite, barite, bauxite, etc.. thyssenkrupp manufactures impact crushers with

The Ultimate Guide to Stone Crusher Plant Design AGICO

2023年2月28日Designing a stone crusher plant requires careful consideration of various factors that can impact the overall efficiency and effectiveness of the crushing process.

(PDF) Design and Performance Evaluation of a Stone Crusher

2021年10月7日Based on the mechanism used crushers are basically of three types; namely, Cone crusher, Jaw crusher, and Impact Crusher. The main objective is to

Crushing Plant Design and Layout Considerations 911

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design

(PDF) Design of impact stone crusher machine

2017年10月1日PDF On Oct 1, 2017, Tesfaye Olana Terefe published Design of impact stone crusher machine Find, read and cite all the research you need on ResearchGate

Environmental GUIDELINE ON STONE CRUSHING plant Mauritius

The operation of a stone crushing plant is associated with several environmental issues, namely:- Site selection Dust and air emissions Noise Wastewater / effluents Solid wastes

Nice design and installation for stone crushing plant YouTube

2023年4月19日We specialize in mining and recycling equipment. We have jaw crushers, impact crusher, cone crusher, mobile crushers, vibrating feeder and screens etc. We ha...

Stone crusher plant design Henan Deya Machinery Co., Ltd.

2022年4月19日There are several ways for the selection of crushing equipment and design of stone crusher plant, the following factors need to be taken into consideration

Impact stone crusher instalation plant desgin

2023年5月12日12 May 2023 Impact stone crushersare used in various industries such as mining, construction, and recycling to reduce the size of rocks and other hard materials.

Industrial Solutions Impact crushers ThyssenKrupp

Stationary impact crusher plant (left) at Cemex, Hermosillo, Mexico Type PB 200/250 Throughput rate 1,200 t/h Right, from top: Semi-mobile impact crusher plant at Jura Cement, Wildegg, Switzerland Type PB 180/200 CR Throughput rate 700 t/h <80 mm 250 t/h <35 mm Stationary impact crusher plant at Loma Negra S.A., Olavarria, Argentina

(PDF) Design and Performance Evaluation of a Stone Crusher

2021年10月7日The machine was fabricated using locally available materials. The fabricated stone crusher was tested and the actual capacity was found to be 301 kg/h with a through-put efficiency of 75.4 %. The

Construction, Working and Maintenance of Crushers for Crushing

dynamic impact. When the material is crushed in an impact crusher, the freely falling material first breaks due to dynamic impact by a moving hammer and then the force of impact accelerates movement of the reduced particles toward breaker blocks and/or other hammers for further size reduction. Dynamic impact has specific advantages for the

Crusher Plants, Rock Crusher Plants, Stone

All stone crusher plants are backed by 365, our aftersales support promising to keep your operation running at full efficiency all year round. With lead times as short as 12 weeks, rock crusher plant

Crushing Plant FlowsheetDesign-Layout 911

2016年3月10日Crushing Plant FlowsheetDesign-Layout In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be

(PDF) Design of Impact Stone crusher machine

Design of Impact Stone crusher machine Tesfaye Olana 2017 Crushers are one of the major size reduction equipment that is used in metallurgical, mechanical, and other similar industries. In industry, crushers are

(PDF) SIZE REDUCTION BY CRUSHING METHODS ResearchGate

2017年3月4日Features of Impact Stone Crusher: 1) Large feesing size ,high crushing cavity,w ide range of the high-hardness of the materials ,large sizes and small ratio of the stone powder pr oducts.

Stone crusher plant design Henan Deya Machinery Co., Ltd.

2022年4月19日In the stone crusher plant processing, the appropriate stone crusher should be chosen based on the different raw materials. First of all, when we categorize the raw materials, we can roughly divide the raw materials into hard stone and soft stone. Hard stone typically includes cobblestone, granite, basalt, whose hardness is basically above

Impact Crushers Design And Calculations GitHub Pages

Impact Crushers Design And Calculations. Impact crusher in the production process, the main parameters of the equipment has an important significance for normal operation, generally includes three basic parameters: the rotor speed, productivity and motor power. So for these impact crusher parameter selection and calculation method of everybody

Impact stone crusher instalation plant desgin

2023年5月12日12 May 2023; Impact stone crushers are used in various industries such as mining, construction, and recycling to reduce the size of rocks and other hard materials. The installation and design of an impact stone crusher plant can significantly impact the productivity, efficiency, and safety of the plant.

(PDF) Design and Performance Evaluation of a Stone Crusher

2021年10月7日The machine was fabricated using locally available materials. The fabricated stone crusher was tested and the actual capacity was found to be 301 kg/h with a through-put efficiency of 75.4 %. The

Industrial Solutions Impact crushers ThyssenKrupp

Stationary impact crusher plant (left) at Cemex, Hermosillo, Mexico Type PB 200/250 Throughput rate 1,200 t/h Right, from top: Semi-mobile impact crusher plant at Jura Cement, Wildegg, Switzerland Type PB 180/200 CR Throughput rate 700 t/h <80 mm 250 t/h <35 mm Stationary impact crusher plant at Loma Negra S.A., Olavarria, Argentina

Crusher Plants, Rock Crusher Plants, Stone

All stone crusher plants are backed by 365, our aftersales support promising to keep your operation running at full efficiency all year round. With lead times as short as 12 weeks, rock crusher plant

Stone Crusher Plant Setup Machinery Partner

Step 1: Extraction and Loading. During loading, the material is extracted and fed into the plant, where it moves into the first step of the crushing setup. A large excavator is the perfect machine for extracting large volumes of material and transporting it to a vehicle or conveyor for feeding. Recommended equipment: Sunward 24 Ton Excavator.

(PDF) Design of Impact Stone crusher machine

Design of Impact Stone crusher machine Tesfaye Olana 2017 Crushers are one of the major size reduction equipment that is used in metallurgical, mechanical, and other similar industries. In industry, crushers are

(PDF) SIZE REDUCTION BY CRUSHING METHODS ResearchGate

2017年3月4日Features of Impact Stone Crusher: 1) Large feesing size ,high crushing cavity,w ide range of the high-hardness of the materials ,large sizes and small ratio of the stone powder pr oducts.

Impact stone crusher instalation plant desgin

2023年5月12日12 May 2023 Impact stone crushersare used in various industries such as mining, construction, and recycling to reduce the size of rocks and other hard materials. The installation and design of an impact stone crusher plant can significantly impact the productivity, efficiency, and safety of the plant.

Stone crusher plant design Henan Deya Machinery Co., Ltd.

2022年4月19日In the stone crusher plant processing, the appropriate stone crusher should be chosen based on the different raw materials. First of all, when we categorize the raw materials, we can roughly divide the raw materials into hard stone and soft stone. Hard stone typically includes cobblestone, granite, basalt, whose hardness is basically above

Impact Crushers Design And Calculations GitHub Pages

Impact crusher in the production process, the main parameters of the equipment has an important significance for normal operation, generally includes three basic parameters: the rotor speed, productivity and motor power. So for these impact crusher parameter selection and calculation method of everybody understand? Following up and have a look.

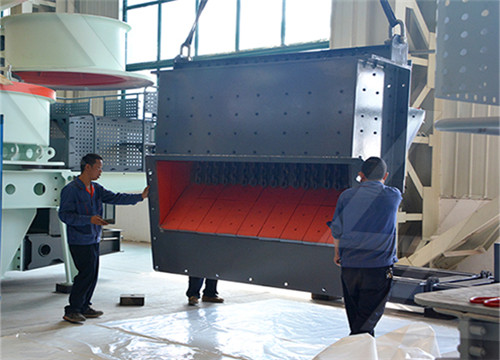

Stone Crusher Installation and Design margot2019

Our stone crushing equipment is the right choice for surface and underground installations at quarries, mines, gravel pits and even recycling plants. Their ease of installation, serviceability, flexibility and productivity make them especially suitable for existing installations or new green-field primary crushing plants.