scalping before gyratory crusher

Going underground: To scalp or not to scalp? Metso

2014年9月22日Scalping is usually recommended before a jaw crusher, whereas gyratory crushers can handle the excavated ore as such. This is because primary gyratories are not as sensitive to fines: they are large, steep and have a relatively short stroke compared to

Influence of jaw crusher parameters on the quality of

2020年6月1日To create variations in minimum and maximum size of the feed material, the materials were scalped at the test plant before being fed to the jaw crusher. The scalper

Jaw Crusher ScienceDirect

2016年1月1日Run of mine granite is passed through a grizzly (45.7 cm) prior to crushing. The ore is to be broken down in a jaw crusher to pass through a 11.5 cm screen. The

进一步探索Difference Between SingleDouble Toggle Jaw CrusherCharacteristics and Comparison of Four Types of Jaw Cru

Gyratory Crusher an overview ScienceDirect Topics

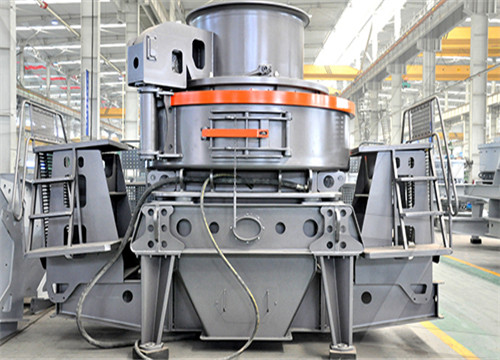

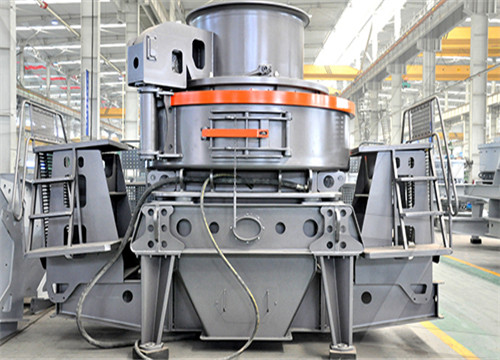

Gyratory Crusher. A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides. From:

Rock Crushing Rule of Thumb 911 Metallurgist

Crusher SelectionCrusher DesignCrusher InstallationCrusher CostsThe Crusher’s Rock BreakersArea of Application

The crushed ore surge pocket beneath a gyratory crusher should have a live load capacity equal to 20 minutes of crusher capacity or the capacityof two pit trucks. Various SourcesIt will take six months to excavate, install, and commission an underground crusher station for a typical jaw crusher. For a very large jaw crusher or a gyratory crusher, it can take nine months. S The crushed ore surge pocket beneath a gyratory crusher should have a live load capacity equal to 20 minutes of crusher capacity or the capacityof two pit trucks. Various SourcesIt will take six months to excavate, install, and commission an underground crusher station for a typical jaw crusher. For a very large jaw crusher or a gyratory crusher, it can take nine months. S...The desired grizzly opening for an underground jaw crusher is equal to 80% of the gape of the crusher. Source: Jack de la VergneThe maximum feed size for a jaw crusher should be about 85% of the gape. Source: Arthur Taggart展开选择时,新内容将添加到焦点当区域上方在911metallurgist上查看更多信息

Crushing and Screening Agg-Net

2012年10月15日Scalping and sizing considerations. The scalping screen is typically fed with material after it has passed through the primary crusher, separating out oversize

Below the surface: Setting up an underground primary

2014年4月1日Scalping is recommended for a jaw crusher for three main reasons: Capacity increases when material below the crusher setting bypasses the crusher. The

Installation of primary crushing equipments with

In this case, it can be proposed to eliminate the percentage of rocks granulometry ≤ 200 mm before blasted rocks pass to crusher, by a proposal to install a scalper that will allow only rocks

Gyratory Crushers 911 Metallurgist

2016年2月17日Essentially, the gyratory crusher consists of a heavy cast-iron, or steel, frame which includes in its lower part an actuating mechanism (eccentric and driving gears), and in its upper part a cone

sbmchina/sbm scalping sebelum crusher gyratory.md at main

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Influence of jaw crusher parameters on the quality of primary

2020年6月1日To create variations in minimum and maximum size of the feed material, the materials were scalped at the test plant before being fed to the jaw crusher. The scalper had elongated openings with slot widths 100 mm and 225 mm. The oversize removal and scalping process enabled the production of five particle size fractions (d/D): 0/400 mm –

Screening media for mining

Gyratory Crusher Wear Plates For best results, we recommend you determine the job your screening media will be serving before selecting the material. If you are unsure, scalping, and aggregate processing. Different materials are employed in the screening media depending on its specific function.

Gyratory Crusher an overview ScienceDirect Topics

Gyratory and Cone Crusher. In Mineral Processing Design and Operations (Second Edition), 2016. 5.1 Introduction. Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher [1].The smaller form is described as a cone crusher. The larger crushers are normally known as

Industrial Solutions Gyratory crushers ThyssenKrupp

Gyratory crushers. State-of-the-art technology with throughput rates of up to 14,000 t/h. Our solutions for the hardest jobs Fields of application and design characteristics.

Best Gyratory Crusher Feeding Scheme Eng-Tips

2010年10月14日We have a gyratory crusher in our mine operation and a grizzly feeder is currently being used to feed the (preventing scalping of ore) and steel plates were put above the bars as an effort to eliminate the problem. This means that all the ore that comes from the mine is not scalped before it gets into the crusher and because

Gyratory Crusher Explained saVRee

A crusher is a machine designed to reduce the size of Run of Mine (ROM) large rocks to smaller rocks, gravel, sand, or rock dust; this is essential for efficient transport of the ore via conveyors etc. Crushing is the first of many stages that lead to separation of the ore from the waste ( gangue) material.

What Type of Crusher Is Best for Primary Crushing? McLanahan

2021年3月25日One additional benefit of a gyratory crusher is that there is no need for pre-screening or scalping of fines in the feed. The crusher can handle the all-in feed. The gradation is controlled by adjusting the spacing between the mantle and the concaves at their closest point.

2. GYRATORY CRUSHERS 911 Metallurgist

GYRATORY CRUSHERS. CRUSHING . 2. GYRATORY CRUSHERS . The original patent for the gyratory crusher was granted to Phile- tus W. Gates in 1881. This fint crusher was used by the Buffalo Cement Co.

Gyratory Crushers 911 Metallurgist

2016年2月17日Essentially, the gyratory crusher consists of a heavy cast-iron, or steel, frame which includes in its lower part an actuating mechanism (eccentric and driving gears), and in its upper part a cone-shaped crushing chamber, lined

sbmchina/sbm scalping sebelum crusher gyratory.md at main

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Influence of jaw crusher parameters on the quality of primary

2020年6月1日To create variations in minimum and maximum size of the feed material, the materials were scalped at the test plant before being fed to the jaw crusher. The scalper had elongated openings with slot widths 100 mm and 225 mm. The oversize removal and scalping process enabled the production of five particle size fractions (d/D): 0/400 mm –

Screening media for mining

Gyratory Crusher Wear Plates For best results, we recommend you determine the job your screening media will be serving before selecting the material. If you are unsure, scalping, and aggregate processing. Different materials are employed in the screening media depending on its specific function.

Gyratory Crusher an overview ScienceDirect Topics

Gyratory and Cone Crusher. In Mineral Processing Design and Operations (Second Edition), 2016. 5.1 Introduction. Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher [1].The smaller form is described as a cone crusher. The larger crushers are normally known as

Crushing and Screening Agg-Net

2012年10月15日Apron feeders are often followed by a heavy-duty scalping screen to separate products or to remove deleterious materials. The scalping screen allows material that is already sized for the final products to bypass the primary crusher. Wobbler feeder Wobbler feeders are typically used for the separation of clays in the feed.

Gyratory Crusher Explained saVRee

A crusher is a machine designed to reduce the size of Run of Mine (ROM) large rocks to smaller rocks, gravel, sand, or rock dust; this is essential for efficient transport of the ore via conveyors etc. Crushing is the first of many stages that lead to separation of the ore from the waste ( gangue) material.

Best Gyratory Crusher Feeding Scheme Eng-Tips

2010年10月14日13 Oct 10 02:04. Thanks for responding Mike. The main problem with the feeder (Humboldt feeder) is that there has been frequent build-up of ore between the section bars (preventing scalping of ore) and steel plates were put above the bars as an effort to eliminate the problem.

FULL PRE-CRUSH TO SAG MILLS ResearchGate

2015年9月20日 The research has led to the inclusion pre-crushers before mills, operating the mills with very high steel ball loads and pebble crushing. It has been reported that pebble crushing can expand...

2. GYRATORY CRUSHERS 911 Metallurgist

GYRATORY CRUSHERS. CRUSHING . 2. GYRATORY CRUSHERS . The original patent for the gyratory crusher was granted to Phile- tus W. Gates in 1881. This fint crusher was used by the Buffalo Cement Co.

sbmchina/sbm scalping sebelum crusher gyratory.md at main

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Optimizing cone crusher performance on clay Crushing,

We have an HP300 crusher in our operations carrying out tertiary crushing duty where it reduces material of P80 32mm to P80 16mm. The ore feed is kimbelite ore which is resulting in a clayish product build up in the crusher discharged chute and crusher cavity which in the last experience resulted in materiel build in the chute blocking it out and

خرید و فروش دولومیت در تایلند

النهائي طحينة طحن مطحنة الكرة

300tons تتبع سعر مصنع تكسير الصخور المتنقلة

آلات ال في تعدين الفوسفات في الأردن

Jual Kebutuhan كل محطم

مطحنة العيون مع يتاى الباترود على الفيس بوك

صور كمبيوتر محطم

مصنعي معامل

تأثير محطم في دبي

ماشین سنگ زنی با قطعات آن

كسارات الصخور روك للبيع في يوتا

الكسارات الكلي للبيع في دبي

الرسومات الفنية لكسارة الصخور

Gyratory Crusher an overview ScienceDirect Topics

Gyratory Crusher. A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides. From:

Rock Crushing Rule of Thumb 911 Metallurgist

Crusher SelectionCrusher DesignCrusher InstallationCrusher CostsThe Crusher’s Rock BreakersArea of Application

The crushed ore surge pocket beneath a gyratory crusher should have a live load capacity equal to 20 minutes of crusher capacity or the capacityof two pit trucks. Various SourcesIt will take six months to excavate, install, and commission an underground crusher station for a typical jaw crusher. For a very large jaw crusher or a gyratory crusher, it can take nine months. S The crushed ore surge pocket beneath a gyratory crusher should have a live load capacity equal to 20 minutes of crusher capacity or the capacityof two pit trucks. Various SourcesIt will take six months to excavate, install, and commission an underground crusher station for a typical jaw crusher. For a very large jaw crusher or a gyratory crusher, it can take nine months. S...The desired grizzly opening for an underground jaw crusher is equal to 80% of the gape of the crusher. Source: Jack de la VergneThe maximum feed size for a jaw crusher should be about 85% of the gape. Source: Arthur Taggart展开选择时,新内容将添加到焦点当区域上方在911metallurgist上查看更多信息

Crushing and Screening Agg-Net

2012年10月15日Scalping and sizing considerations. The scalping screen is typically fed with material after it has passed through the primary crusher, separating out oversize

Below the surface: Setting up an underground primary

2014年4月1日Scalping is recommended for a jaw crusher for three main reasons: Capacity increases when material below the crusher setting bypasses the crusher. The

Installation of primary crushing equipments with

In this case, it can be proposed to eliminate the percentage of rocks granulometry ≤ 200 mm before blasted rocks pass to crusher, by a proposal to install a scalper that will allow only rocks

Gyratory Crushers 911 Metallurgist

2016年2月17日Essentially, the gyratory crusher consists of a heavy cast-iron, or steel, frame which includes in its lower part an actuating mechanism (eccentric and driving gears), and in its upper part a cone

sbmchina/sbm scalping sebelum crusher gyratory.md at main

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Influence of jaw crusher parameters on the quality of primary

2020年6月1日To create variations in minimum and maximum size of the feed material, the materials were scalped at the test plant before being fed to the jaw crusher. The scalper had elongated openings with slot widths 100 mm and 225 mm. The oversize removal and scalping process enabled the production of five particle size fractions (d/D): 0/400 mm –

Screening media for mining

Gyratory Crusher Wear Plates For best results, we recommend you determine the job your screening media will be serving before selecting the material. If you are unsure, scalping, and aggregate processing. Different materials are employed in the screening media depending on its specific function.

Gyratory Crusher an overview ScienceDirect Topics

Gyratory and Cone Crusher. In Mineral Processing Design and Operations (Second Edition), 2016. 5.1 Introduction. Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher [1].The smaller form is described as a cone crusher. The larger crushers are normally known as

Industrial Solutions Gyratory crushers ThyssenKrupp

Gyratory crushers. State-of-the-art technology with throughput rates of up to 14,000 t/h. Our solutions for the hardest jobs Fields of application and design characteristics.

Best Gyratory Crusher Feeding Scheme Eng-Tips

2010年10月14日We have a gyratory crusher in our mine operation and a grizzly feeder is currently being used to feed the (preventing scalping of ore) and steel plates were put above the bars as an effort to eliminate the problem. This means that all the ore that comes from the mine is not scalped before it gets into the crusher and because

Gyratory Crusher Explained saVRee

A crusher is a machine designed to reduce the size of Run of Mine (ROM) large rocks to smaller rocks, gravel, sand, or rock dust; this is essential for efficient transport of the ore via conveyors etc. Crushing is the first of many stages that lead to separation of the ore from the waste ( gangue) material.

What Type of Crusher Is Best for Primary Crushing? McLanahan

2021年3月25日One additional benefit of a gyratory crusher is that there is no need for pre-screening or scalping of fines in the feed. The crusher can handle the all-in feed. The gradation is controlled by adjusting the spacing between the mantle and the concaves at their closest point.

2. GYRATORY CRUSHERS 911 Metallurgist

GYRATORY CRUSHERS. CRUSHING . 2. GYRATORY CRUSHERS . The original patent for the gyratory crusher was granted to Phile- tus W. Gates in 1881. This fint crusher was used by the Buffalo Cement Co.

Gyratory Crushers 911 Metallurgist

2016年2月17日Essentially, the gyratory crusher consists of a heavy cast-iron, or steel, frame which includes in its lower part an actuating mechanism (eccentric and driving gears), and in its upper part a cone-shaped crushing chamber, lined

sbmchina/sbm scalping sebelum crusher gyratory.md at main

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Influence of jaw crusher parameters on the quality of primary

2020年6月1日To create variations in minimum and maximum size of the feed material, the materials were scalped at the test plant before being fed to the jaw crusher. The scalper had elongated openings with slot widths 100 mm and 225 mm. The oversize removal and scalping process enabled the production of five particle size fractions (d/D): 0/400 mm –

Screening media for mining

Gyratory Crusher Wear Plates For best results, we recommend you determine the job your screening media will be serving before selecting the material. If you are unsure, scalping, and aggregate processing. Different materials are employed in the screening media depending on its specific function.

Gyratory Crusher an overview ScienceDirect Topics

Gyratory and Cone Crusher. In Mineral Processing Design and Operations (Second Edition), 2016. 5.1 Introduction. Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher [1].The smaller form is described as a cone crusher. The larger crushers are normally known as

Crushing and Screening Agg-Net

2012年10月15日Apron feeders are often followed by a heavy-duty scalping screen to separate products or to remove deleterious materials. The scalping screen allows material that is already sized for the final products to bypass the primary crusher. Wobbler feeder Wobbler feeders are typically used for the separation of clays in the feed.

Gyratory Crusher Explained saVRee

A crusher is a machine designed to reduce the size of Run of Mine (ROM) large rocks to smaller rocks, gravel, sand, or rock dust; this is essential for efficient transport of the ore via conveyors etc. Crushing is the first of many stages that lead to separation of the ore from the waste ( gangue) material.

Best Gyratory Crusher Feeding Scheme Eng-Tips

2010年10月14日13 Oct 10 02:04. Thanks for responding Mike. The main problem with the feeder (Humboldt feeder) is that there has been frequent build-up of ore between the section bars (preventing scalping of ore) and steel plates were put above the bars as an effort to eliminate the problem.

FULL PRE-CRUSH TO SAG MILLS ResearchGate

2015年9月20日 The research has led to the inclusion pre-crushers before mills, operating the mills with very high steel ball loads and pebble crushing. It has been reported that pebble crushing can expand...

2. GYRATORY CRUSHERS 911 Metallurgist

GYRATORY CRUSHERS. CRUSHING . 2. GYRATORY CRUSHERS . The original patent for the gyratory crusher was granted to Phile- tus W. Gates in 1881. This fint crusher was used by the Buffalo Cement Co.

sbmchina/sbm scalping sebelum crusher gyratory.md at main

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Optimizing cone crusher performance on clay Crushing,

We have an HP300 crusher in our operations carrying out tertiary crushing duty where it reduces material of P80 32mm to P80 16mm. The ore feed is kimbelite ore which is resulting in a clayish product build up in the crusher discharged chute and crusher cavity which in the last experience resulted in materiel build in the chute blocking it out and